What can ELEMET offer you?

And we know you do, too.

Our #1 goal is to avoid or minimize landfill use through legitimate metal and mineral reclamation or transformation and repurposing of your materials.

We value our planet

We provide regulatory assistance on transportation and recycling of byproducts in full compliance with the relevant waste regulations.

Specialized processing

Lean on our experience

Our partnerships with global recycling & processing entities allow us to offer highly competitive solutions to your secondary scrap challenges.

Streamline your workflow

International relationships

Our processing capabilities scale from small to multi-million pound industrial metal recovery streams

An established audience

A perfect fit

Recycling is easy with our turnkey solutions - just one point of contact to service your account fully and sustainably

Turnkey project management

Our processing capabilities allow us to recover and return value from byproducts, wastes, off-spec and obsolete materials

Streamline your workflow. Want to save on processing costs and gain greater control over your outcomes? We can help with equipment and process flow solutions, including procurement, permitting, installation, and commissioning.

Access to the global trade marketplace for recovered organic and inorganic raw materials means that we can take on your hard-to-place materials

Learn more about ELEMET’s recyling strengths

Click the links below for more information

None of these describe your material? It’s likely we can still help! Fill out our recycling form and we will get to work on a solution for you!

Alkaline Solutions

An alkaline solution is a mixture of base solids dissolved in water.

The potential of hydrogen, also known as the pH scale, measures the alkalinity or acidity level of a solution. The scale ranges from zero to 14. The midpoint 7 represents a neutral pH. A neutral solution is neither an acid nor alkaline. pH levels below 7 indicate an acidic solution, and numbers above 7 indicate an alkaline solution.

Some examples of alkaline solutions include sodium hydroxide, potassium hydroxide, magnesium hydroxide and calcium carbonate. Each of these solutions has different applications in different industries.

Manufacturers commonly use alkaline solutions in products such as bio-diesel fuels, soaps, medications, detergents and cleaning products. Additionally, manufacturers use alkaline solutions in many food preparations and specialized applications. As cleaning agents alkaline solutions can dissolve fats, grease, oils and protein.

Sodium Hydroxide, also known as lye and caustic soda, is an alkaline solution with a strong chemical base. Manufacturers use this solution in textiles, soaps, drinking water and paper. Sodium hydroxide is hygroscopic, meaning it absorbs water from the air and so this alkaline solution must be stored in an airtight container. Sodium hydroxide can also be used to dissolve certain types of metals and compounds. In food preparations, sodium hydroxide can be used to chemically wash or peel foods, to process fruits, vegetables and cocoa and to scald poultry.

Potassium Hydroxide, also known as caustic potash, is an inorganic compound that also functions as an alkaline solution. Potassium hydroxide has several different applications including use in the manufacturing of diesel, soft soaps and as an electrolyte in alkaline batteries.

Many alkaline solutions including potassium hydroxide can cause severe chemical burns. You should always take extreme precaution while handling any alkaline solution.

Tell us what you have and we’ll see how we can help you.

Baghouse Collection Fines and Filters

A baghouse filter also known as a bag filter or fabric filter is an air pollution control device and dust collector which removes particulates released from commercial processes.

Power plants, steel mills, pharmaceutical producers, food manufacturers, chemical producers and other industrial companies often use baghouses to control emission of air pollutants.

Baghouses came into widespread use in the late 1970s after the invention of high-temperature fabrics (for use in the filter media) capable of withstanding temperatures over 350 °F (177 °C).

Unlike electrostatic precipitators, where performance may vary significantly depending on process and electrical conditions, functioning baghouses typically have a particulate collection efficiency of 99% or better, even when particle size is very small.

Tell us what you have and we’ll see how we can help you.

Byproducts such as Slag, Dross, Scale, Filings or Skimmings

Many industrial manufacturing processes produce a variety of byproducts.

Slag is a by-product of the smelting process used to process ores and secondary or scrap metals. Broadly, it can be classified as ferrous (by-products of processing iron and steel), ferroalloy (by-product of ferroalloy production) or non-ferrous/base metals (by-products of recovering non-ferrous materials like copper, nickel, zinc and phosphorus).

Within these general categories, slags can be further categorized by their precursor and processing conditions such as:

Blast Furnace (BF) slag

Aircooled Blast Furnace (ACBF) slag

Basic Oxygen Furnace (BOF) slag

Electric Arc Furnace (EAF) slag

Dross is a mass of solid impurities floating on molten metal or dispersed in the metal, such as in wrought iron. It forms on the surface of low-melting-point metals such as tin, lead, zinc or aluminum or by oxidation of the metal. For higher melting point metals and alloys such as steel and silver, oxidized impurities melt and float making them easy to pour off.

Dross, as a solid, is distinguished from slag, which is a liquid. Dross product is not entirely waste material; for example, aluminum dross can be recycled and is used in secondary steel manufacturing for slag deoxidation.

These are also often referred to as skimmings.

Filings are derived by a material removal process in manufacturing. Similar, depending on use, to both sawing and grinding in effect, it is functionally versatile, but used mostly for finishing operations, namely in deburring operations. Filing operations can be used on a wide range of materials as a finishing operation. Filing helps achieve workpiece function by removing excess material and deburring the surface.

Types of filing processes include:

Band filing, which takes place using a machine similar to a belt sander or band saw. A band filing operation can be used to remove small amounts of material with good accuracy.

Reciprocating filing, which takes place on a flat surface where workpieces are fed into the file. The file teeth are angled so that material is removed on each downstroke of the tool. Chips removed from the workpiece fall through a cavity in front of the file.

Tell us what you have and we’ll see how we can help you.

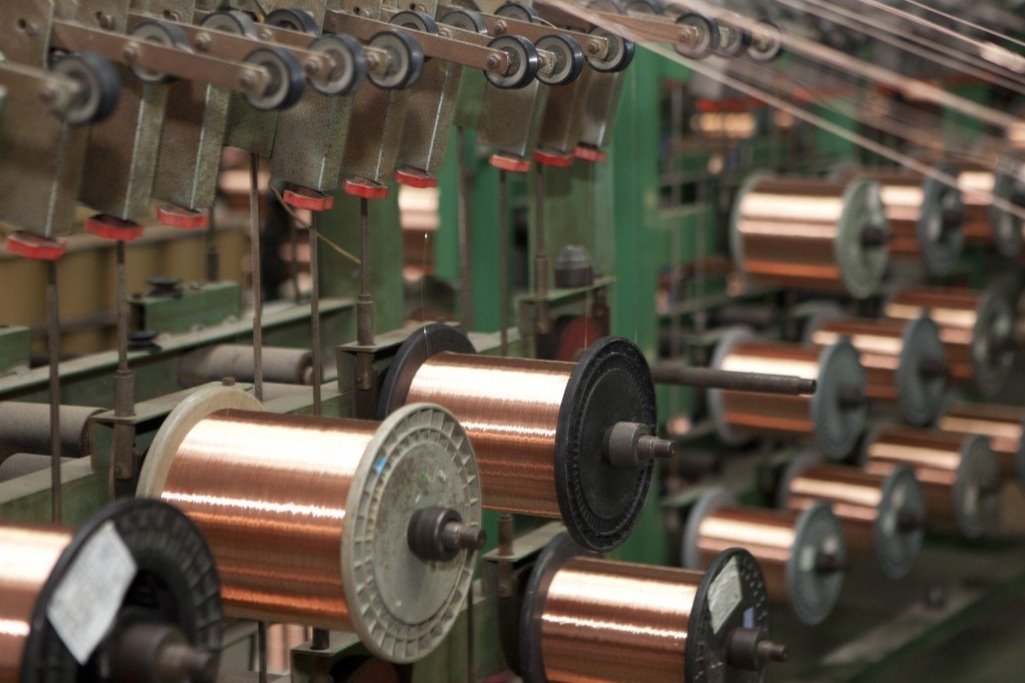

Wire Drawing Muds

Wire drawing is a process used to reduce the diameter of a wire by pulling the wire through a single, or series of, drawing dies.

There are many applications for wire drawing, including electrical wiring, cables, tension-loaded structural components, springs, paper clips, spokes for wheels, and stringed musical instruments.

Lubrication in the drawing process is essential for maintaining good surface finish and long die life. Here are a few methods of lubrication:

Wet drawing - The dies and wire or rod are completely immersed in lubricants

Dry drawing - The wire or rod passes through a container of lubricant which coats the surface of the wire or rod

Metal coating - The wire or rod is coated with a soft metal which acts as a solid lubricant

Various lubricants, such as oil, are employed. Another lubrication method is to immerse the wire in a copper sulfate solution, so that a thin film of copper is deposited which forms a kind of lubricant. In some classes of wire the copper is left after the final drawing to serve as a rust preventative or to allow easy soldering. The best example of copper coated wire is in MIG wire used in welding.

These oils &/or lubricants are collected and sent off for reuse or recycle/recovery.

Tell us what you have and we’ll see how we can help you.

Our e-waste program gives you the peace of mind you deserve

Easily recycle your outdated and nonworking electronics and know that your materials are being handled responsibly and securely.

Complete data destruction

At our facility, your data is destroyed in compliance with US Department of Defense standards.

A customized recycling program tailored to your needs

From pickups on your schedule to employee recycling programs, we can provide you with multiple options to manage your e-waste so that you can find the perfect fit.

Certificates of recycling and data destruction

Our thorough documentation gives you the assurance you need and the security your sensitive materials require.

Years of experience leading the way in recycling solutions

From logistics to processing to program management, let our collective experience help your organization recycle easily and responsibly.

Thank you for your interest in electronics recycling with ELEMET.

Please be aware that we are currently only taking deliveries and receipt of electronics from commercial accounts and have a minimum lot size of 500 lbs. We do not accept any CRT-containing devices of any kind.

In addition to buying materials, there are many items that ELEMET can recycle free of charge. Please contact Alex Delia (adelia@elemet.net) for more information.

We purchase:

Adapters

Aluminum

Brass

Circuit Board

Backplane board

Finger Board

Mother Board

Power Board

Server Board

Computers

Desktops

Laptops

Non-CRT All-in-Ones

Terminals and Workstations

Copper

Electric Motors

Equipment Control Boxes and Components

Hard Drives

Networking Equipment

Modems

Routers

Switches

Power Supplies

Pumps

RAM and Processors

Servers

Stainless Steel

Test and Lab Equipment

Telecommunications Equipment

Transformers

UPS

Wire

If you are an individual or represent a small business of under 50 employees or a non-for-profit corporation with under 75 employees, then you qualify for “free and convenient” recycling of electronic waste.

If you do not wish to recycle your electronics with ELEMET - For free and convenient electronic waste recycling options, please visit the NYS Department of Environmental Conservation’s website at https://www.dec.ny.gov/chemical/66872.html.

Fuel Cells

A fuel cell is an electrochemical cell that converts the chemical energy of a fuel (often hydrogen) and an oxidizing agent (often oxygen) into electricity through a pair of redox reactions. Fuel cells can produce electricity continuously for as long as fuel and oxygen are supplied.

Fuel cells come in many varieties. However, they all work in the same general manner. They are made up of three adjacent segments: the anode, the electrolyte, and the cathode. Two chemical reactions occur at the interfaces of the three different segments. The net result of the two reactions is that fuel is consumed, water or carbon dioxide is created, and an electric current is created, which can be used to power electrical devices, normally referred to as the load.

Design features in a fuel cell include:

The electrolyte substance, which usually defines the type of fuel cell, and can be made from a number of substances like potassium hydroxide, salt carbonates, and phosphoric acid.

The fuel that is used. The most common fuel is hydrogen.

The anode catalyst, usually fine platinum powder, breaks down the fuel into electrons and ions.

The cathode catalyst, often nickel, converts ions into waste chemicals, with water being the most common type of waste.

There are currently 23 different types and configurations of fuel cells in use.

Power

Stationary fuel cells are used for commercial, industrial and residential primary and backup power generation. Fuel cells are very useful as power sources in remote locations, such as spacecraft, remote weather stations, large parks, communications centers, rural locations including research stations, and in certain military applications.

Cogeneration

Combined heat and power (CHP) fuel cell systems are used to generate both electricity and heat for homes, office building and factories. The system generates constant electric power (selling excess power back to the grid when it is not consumed), and at the same time produces hot air and water from the waste heat.

Fuel Cell Electric Vehicles

A number of different types of vehicles are now using fuel cells.

Automobiles

By year-end 2019, about 18,000 FCEVs had been leased or sold worldwide. Three fuel cell electric vehicles have been introduced for commercial lease and sale. Fuel cell electric vehicles feature an average range of 314 miles between refuelings. They can be refueled in less than 5 minutes.

Buses

There are over 100 buses powered by fuel cells in service around the world. Fuel cell buses have from 39% to 141% higher fuel economy than diesel buses and natural gas buses.

As of 2019, the National Renewable Energy Laboratory was evaluating several current and planned fuel cell bus projects in the U.S.

Trucks

In December 2020, several major corporations announced they have agreed to consider introducing light-duty fuel cell electric trucks (light-duty FCETs). In August 2021, Toyota announced their plan to make fuel cell modules at its Kentucky auto-assembly plant for use in zero emission big rigs and heavy-duty commercial vehicles. They plan to begin assembling the electrochemical devices in 2023.

Forklifts

In 2013 there were over 4,000 fuel cell forklifts used in material handling in the US. Fuel cell fleets are operated by various major companies. Pike Research projected in 2011 that fuel cell-powered forklifts would be the largest driver of hydrogen fuel demand by 2020.

Most companies in Europe and the US do not use petroleum-powered forklifts, as these vehicles work indoors where emissions must be controlled and instead use electric forklifts. Fuel cell-powered forklifts can provide benefits over battery powered forklifts as they can be refueled in 3 minutes and they can be used in refrigerated warehouses, where their performance is not degraded by lower temperatures. The FC units are often designed as drop-in replacements.

Submarines

The Type 212 submarines of the German and Italian navies use fuel cells to remain submerged for weeks without the need to surface.

Portable power systems

Portable fuel cell systems are generally classified as weighing under 10 kg and providing power of less than 5 kW. The potential market size for smaller fuel cells is quite large with an up to 40% per annum potential growth rate and a market size of around $10 billion, leading a great deal of research to be devoted to the development of portable power cells. Within this market two groups have been identified. The first is the micro fuel cell market, in the 1-50 W range for power smaller electronic devices. The second is the 1-5 kW range of generators for larger scale power generation (e.g., military outposts, remote oil fields).

We are able to handle fuel cells with various formats and applications. Tell us what you have and we’ll see how we can help you.

Ethylene Glycol

Ethylene glycol is an organic compound with the formula (CH2OH)2. It is mainly used for two purposes - as a raw material in the manufacture of polyester fibers and for antifreeze formulations.

The major use of ethylene glycol is as an antifreeze agent in automobile & truck coolant and in air-conditioning systems that either place the chiller or air handlers outside or must cool below the freezing temperature of water.

In geothermal heating/cooling systems, ethylene glycol is the fluid which transports heat through the use of a geothermal heat pump. The ethylene glycol either gains energy from the source (lake, ocean, water well) or dissipates heat to the sink, depending on whether the system is being used for heating or cooling.

Ethylene glycol is also used as a de-icing fluid for windshields and aircraft, and as a component of vitrification (anticrystallization) mixtures for low-temperature preservation of biological tissues and organs.

Ethylene glycol is used in the natural gas industry to remove water vapor from natural gas before further processing. Because of its high boiling point and affinity for water, ethylene glycol is a useful desiccant. Ethylene glycol is widely used to inhibit the formation of natural gas hydrates in long multiphase pipelines that convey natural gas from remote gas fields to a gas processing facility.

Ethylene glycol can be recovered from the natural gas and reused as an inhibitor after purification treatment that removes water and inorganic salts.

Minor uses of ethylene glycol include the manufacture of capacitors, as a chemical intermediate in the manufacture of 1,4-dioxane, as an additive to prevent corrosion in liquid cooling systems for personal computers, and inside the lens devices of cathode-ray tube type of rear projection televisions.

Ethylene glycol is commonly used as a preservative for biological specimens, especially in secondary schools during dissection as a safer alternative to formaldehyde. It is also used as part of the water-based hydraulic fluid used to control subsea oil and gas production equipment.

Tell us what you have and we’ll see how we can help you.

Recycling solutions for thermal spray byproducts

We provide customized recycling solutions for byproducts from HVOF, HVAF, and other heat treatment industry processes. Whether your applications are refractory coatings, thermal protection for high-performance materials, wear-control or corrosion-preventative coatings, we can handle your byproducts.

Schedule pickups for your oxides and overspray according to your production schedule and eliminate space and storage concerns.

Let us help you stay focused on what’s important to you - making a quality product that can stand up to demanding, specialized applications.

Metal-Bearing Acids

Acids are used in many different industrial applications.

Sulfuric acid is one of the most used acids in industry. It is used to refine metals, and it has a role in the manufacture of fertilizers. Sulfuric acid is also used to refine petroleum and pickle several metals.

Hydrochloric acid is used to clean oil wells and metals. It is also important in the manufacture of various foods and such substances as calcium chloride.

Nitric acid is used in the manufacture of the fertilizer ammonium nitrate. Phosphoric acid has plenty of uses in industry, such as in the manufacture of medicines, chemicals and food. It is also used in construction.

Citric acid is mostly used in the manufacture of foods and beverages. It is also used as a preservative in the biochemistry industry.

Dilute acetic acid is another widely used acid in industrial processes, especially in the manufacture of chemical solutions. It is normally used as a chemical reagent in the manufacture of chemicals such as ester, acetic anhydride and acetate monomer.

Other widely used acids in industry include formic acid, oxalic acid and acetic acid glacial.

Tell us what you have and we’ll see how we can help you.

Metal Hydroxides

A hydroxide is any chemical compound which contains one or more groups, each of which comprises an oxygen and hydrogen atom bound and functioning as the negatively charged OH-ion. Hydroxides include known laboratory alkalis and industrial processes.

A few examples of hydroxide materials we work with are:

Aluminum hydroxide is a basic inorganic amphoteric compound used as an intermediate in organic synthesis and as an additive in the pharmaceutical and fine chemical industries.

Cobalt hydroxide (II) is a commercial catalyst that has porous structure for a high catalytic effect in refining and petrochemical manufacturing.

Copper (II) hydroxide is used as a broad-spectrum foliar fungicide in fruits, vegetables and ornamental plants.

Gold hydroxide (III) is used in medicine, porcelain making, gold plating. The gold hydroxide deposited on suitable carriers can be used for the preparation of gold catalysts

Iron hydroxide (II) is also known as ferrous hydroxide or green oxide, is an inorganic compound with very little solubility in water.

Nickel hydroxide (II) is a green, crystalline and inorganic compound that produces toxic gases when heating. Nickel hydroxide is used in nickel-cadmium batteries and as a catalyst in chemical reactions.

Tell us what you have and we’ll see how we can help you.

Custom solutions for off-spec, contaminated and obsolete materials

We know your proprietary materials need responsible, honest handling.

Let us be the worry-free turnkey solution that gives you back the time and energy demanded by managing disposal of sensitive materials.

We coordinate with your Environmental Health and Safety team to assess the individual challenges your company faces with regard to disposal of your rejected materials. We stay current on state and federal regulations, keep a well-documented chain of custody, and coordinate pickups and drop-offs on your schedule.

At the end of our process, we provide a certificate of destruction or certificate of consumption. You’ll know that everything has gone according to plan and have the paper trail to back it up.

We serve many industries with high-security proprietary materials and parts that require special handling when they do not meet specification or become obsolete. Our case history includes recycling programs for the aerospace, automotive, fuel cell and chemical industries. We’ve built the toolkit to help us find innovative solutions for your problem materials - let us know what we can help you with today.

Petroleum Refining Byproducts

The petroleum refining industry utilizes a large variety of catalysts to facilitate various refining processes.

Cracking processes utilize silica, alumina, or zeolite substrates.

Hydrogenation processes utilize nickel, platinum, or palladium as reaction promoters.

Steam reforming utilizes nickel as the reaction promoter.

Hydrocracking uses platinum or palladium as the reaction promoter. Other hydrocracking catalysts may use cobalt, molybdenum, or nickel as the reactor promoter.

The petroleum refining industry churns out millions of pounds each year of spent catalysts.

Virtually all have metals content of such value that cost-effective recovery and recycling options are most often utilized. Some of these are the promoter metals. Other metals are ‘trapped’ on the catalyst during its usage but have recoverable economic value, such as vanadium.

In addition, these plants have significant air pollution control equipment which relies on catalysts containing platinum, palladium, and/or rhodium to effectively clean the air being emitted from various pieces of equipment. These pollution control catalysts also must be regularly replaced.

Last, virtually all refineries have significant filtration requirements. Capturing a wide variety of solids with varying metals from other waste streams generated at the refiner site. These can include: refinery water treatment plants, cooling tower operations, etc.

Tell us what processes and materials your plant utilizes and we’ll see how we can help you.

Photographic and X-Ray Film and Wastes

Photographic film (including x-ray film) is a byproduct. Byproducts are considered a recyclable material (not subject to regulation) when sent for reclamation.

However, photographic film is regulated as a general solid waste (non-special) when sent for disposal. If the photographic film exhibits the characteristics of a hazardous waste, it is a hazardous waste when sent for disposal.

Silver flake (from an electrolytic recovery process) is considered a product (not subject to regulation) when sent for silver recovery. When sent for disposal, it is a special waste and may be a hazardous waste if it exhibits the characteristics of a hazardous waste.

Spent developing solutions and silver traps (steel wool or ion-exchange canisters) are spent materials. Therefore, they are special wastes and may be hazardous if they exhibit the characteristics of a hazardous waste.

If the sludge from a steel wool silver trap is removed and handled separately, it would be considered a sludge (characteristic) which is not subject to the waste management regulations when sent for non-listed reclamation.

Tell us what you have and we’ll see how we can help you.

Spent and Surplus Catalysts

We refine and recover metal-containing catalysts from many different industries including petrochemical, automotive, fuel cell, nutrition and beauty, aerospace and pharmaceuticals.

Catalysts are compounds that speed up chemical reactions by lowering the energy barrier between reactants and products. Not only do they save energy, they can also help to produce a pure product instead of a mixture.

Because of this, catalysts are used in many industrial processes. For example, they can be used in refining petroleum to break long chain hydrocarbon molecules into smaller ones, producing ammonia in the Haber process, or in synthesizing compounds for the pharmaceutical industry.

Our flexibility allows us to take on large and small recycling prohects as well as coordinating both one-time and scheduled pick-ups, so that you can recycle on a scale and schedule that works for you.

Tell us what you have and we’ll see how we can help you.